Yesterday

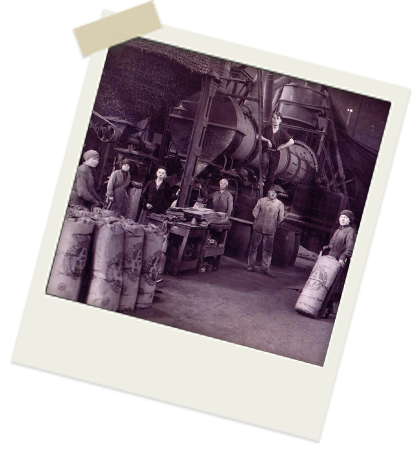

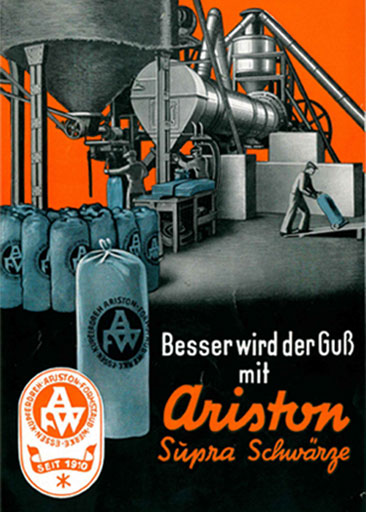

ARISTON Formstaub-Werke were founded in 1910 and had their headquarters at the former Adler colliery site in Essen-Kupferdreh. The main focus was the production of blackings for foundries.

Following the merger with Phoenix-Gießerie-Bedarfsgesellschaft mbH in 1967, the company headquarters moved to Altendorf-Rohr (now Essen-Burgaltendorf). The result of the merger was a modern production company that would be able to dry and grind coke and produce mixed products in one economical process sequence.

Today

Through constant investment and development work, ARISTON Formstaub-Werke has developed over the years into one of the most modern and solid companies in the industry, which today supplies many different products for a wide range of applications to customers all over the world.

ARISTON Formstaub-Werke has been certified according to DlN EN ISO 9001 since 1996. The term “quality” was thus concretized and applied to the individual raw material, packaging and delivery options.

Since 2008, the company’s own vehicle fleet has been further expanded and a new truck with tipper body and a new truck with silo tipper trailer have been purchased.

In 2010, the company’s own truck scales up to 50 tons were put into operation. In the same year, the laboratory was completely renovated and continuously adapted to today’s requirements.

In 2012, the screening capacity was increased by 100% with the purchase of a new high-performance Mogensen screening machine.

In 2014, 2 ferromagnetic separation systems were implemented in production to further increase the purity of the finished products.

In 2015, the production halls were extensively renovated and equipped with modern building technology

and LED lighting.

In 2016, the existing diesel forklift trucks were replaced with state-of-the-art electric forklift trucks as part of environmental protection and occupational safety. There are now 8 electric lifting tools in operation.

In 2017, an old warehouse was extensively modernized.

In 2018, the existing silo facilities in the outdoor area were renovated and equipped with state-of-the-art weighing cells. In the same period, the raw material silos were also converted to weighing cell technology.

In 2019, the grinding plant was expanded to include a protective sieving system to reliably and permanently separate coarse spray grain. The mixing silos were expanded by another to 3 mixing silos.

The digital office was implemented in 2020 and extended to the entire production and laboratory in subsequent years. Industrial filter systems were massively expanded to ensure long-term employee protection.

In 2021, all yard and path areas were extensively renovated and another warehouse was built. Old façade areas were renovated to improve energy efficiency. A container loading ramp was purchased to minimize container loading times, the number of which is constantly increasing.

In 2022, another energy-efficient tractor unit was purchased for the vehicle fleet. By further expanding the office building, 2 new company apartments were made ready for occupancy.

In 2023, the new rotary drum kiln was put into operation to further increase the previous

drying capacity of the wet raw materials once again. Mobile filling systems were developed to make production processes even more flexible.

ARISTON Formstaub-Werke’s international focus and maximum productivity and flexibility ensure that it will continue to be a competent and reliable partner for the industry in the future.